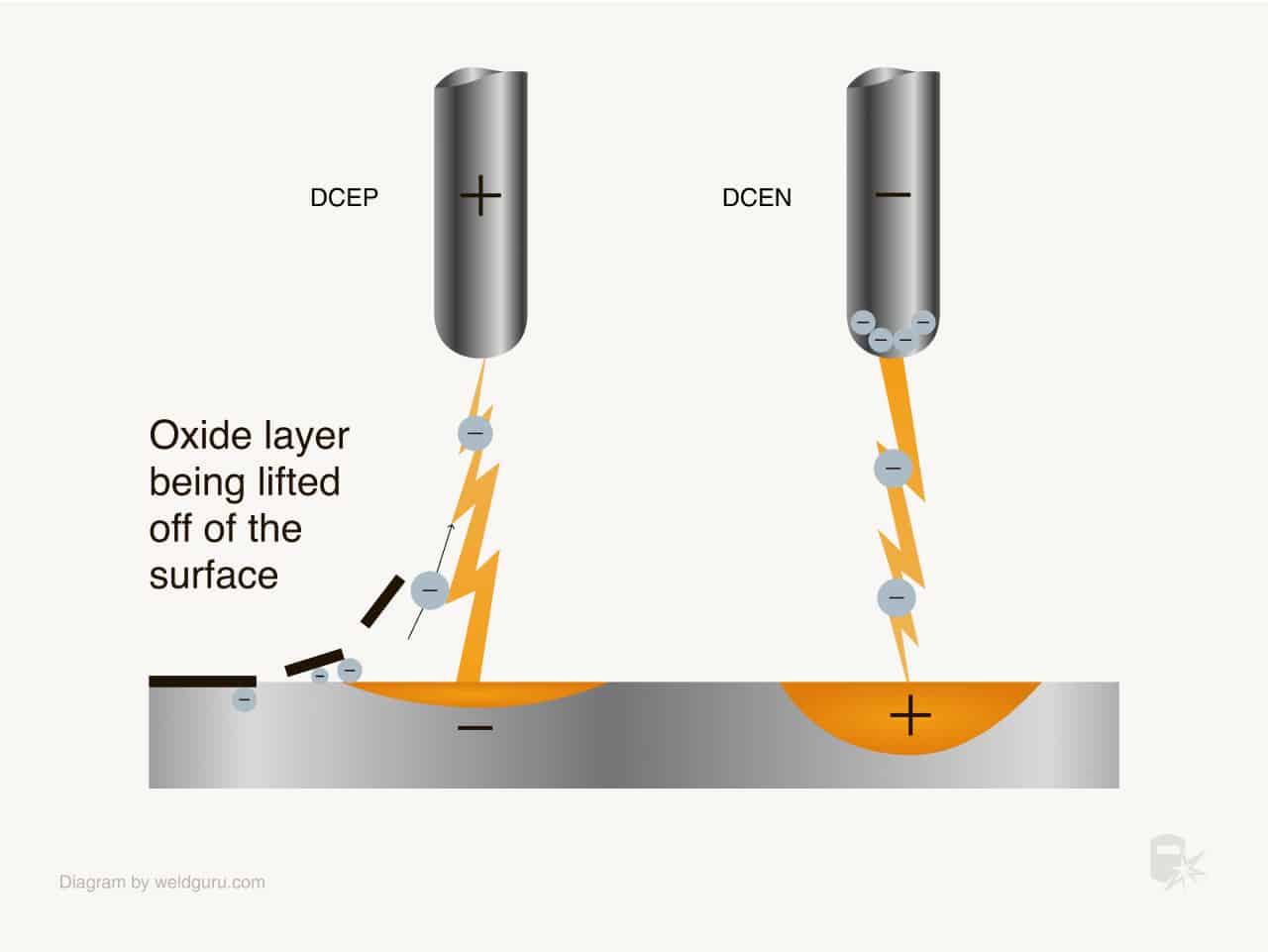

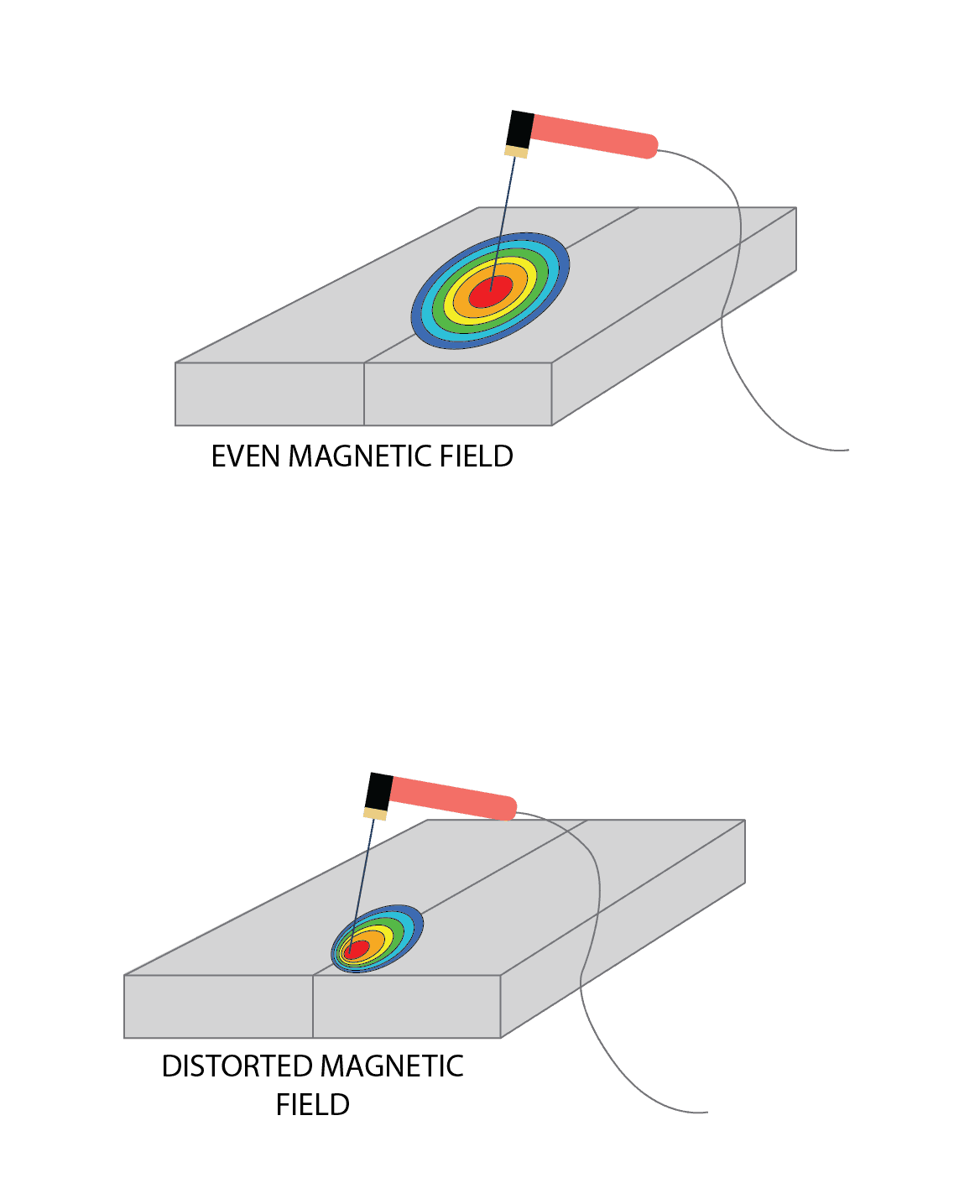

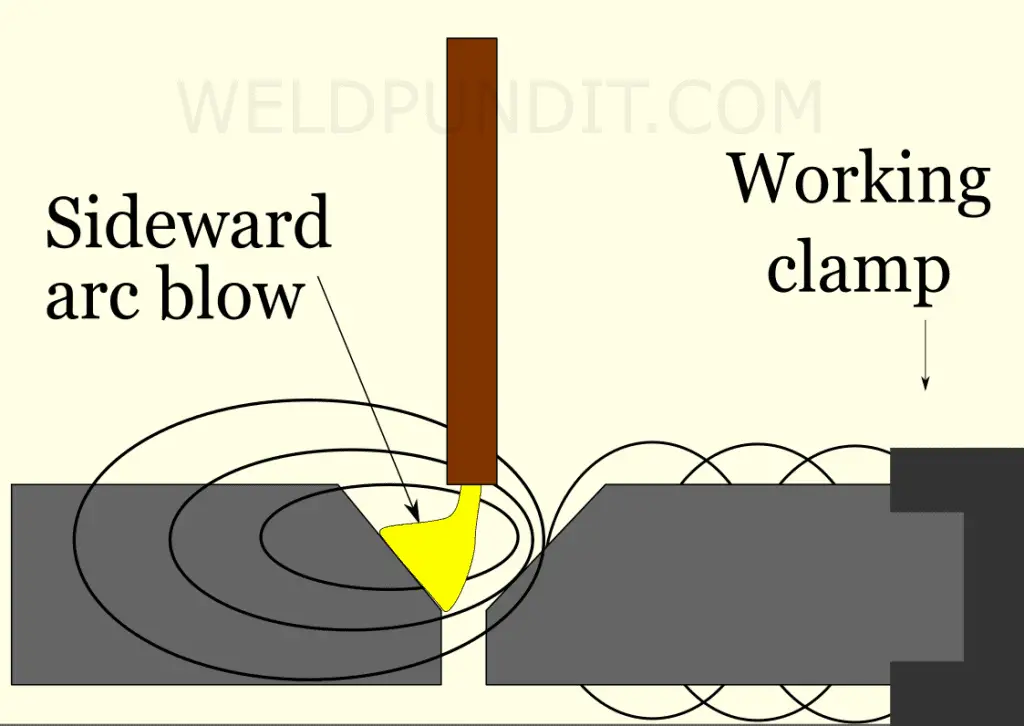

Arc blow welding is a phenomenon that occurs during welding when the arc is deflected from its intended path, causing the weld to be of poor quality. There are several types of arc blow welding, including: Direct Current Arc Blow (DCAB): Direct Current Arc Blow occurs when using direct current (DC) welding power sources. The arc is deflected.. Magnetic Arc Blow. As previously mentioned, the magnetic arc blow is caused by unbalanced magnetic field surrounding welding arc on DC arc welding. Imbalance magnetic field exists due to change the direction of the current when it flows from the electrode to the base metal through the arc, and due to that, the arc is always at varying distance.

Advanced Shielded Metal Arc Welding 1 Diagram Quizlet

WHAT IS ARC BLOW IN WELDING? YouTube

Miller AC/DC Gas Tungsten ARC Welding Machines, Model 330A/BP; SN SN

Arc Welding Explained What Is It & How Does It Work? Weld Guru

AC vs. DC Welding Differences Compared (with Pros & Cons)

Powercraft DC ARC Inverter Welding Machine (Multi Voltage) PIW 300 MV

Difference between AC and DC welding, ,Bare and coated electrode , ARC

Powercraft DC ARC Inverter Welding Machine 160A (PIW 160) Powercraft

Arc blow in DC welding YouTube

MIG 200A IGBT Inverter DC Welder 3in1 MMA TIG Gas GASLESS ARC Welding

Insider's Guide to Submerged Arc Welding (SAW) Insider

ARC BLOW WeldTech Education

POLARITY IN DC ARC WELDING WELD TECH EDUCATION

Arc welding up close YouTube

Powercraft DC ARC Inverter Welding Machine PIW 205I Powercraft

The Basics of Electricity in Welding

TransTig 170 MV MultiVoltage DC TIG ARC Welder Boxed Set MigAnglia

4 Ways to Eliminate Arc Blow YouTube

The Welding Arc Blow Guide Causes, Defects, Remedies

Arc Blow Causes and Prevention for Sound Welds Insider

Reduce the welding current - which may require a reduction in arc speed. Angle the electrode with the work opposite the direction of arc blow, as illustrated in Figure 3-45. Make a heavy tack weld on both ends of the seam; apply frequent tack welds along the seam, especially if the fitup is not tight.. What is arc blow and when does it occur? Arc blow is a defect that can occur when welding with a direct current. It is caused by a magnetic field that sets up in the steel plate being welded, and this causes the arc to flutter and blow, making it difficult to control. An Arc crater is an area of the weld that has been damaged by an arc blow.